|

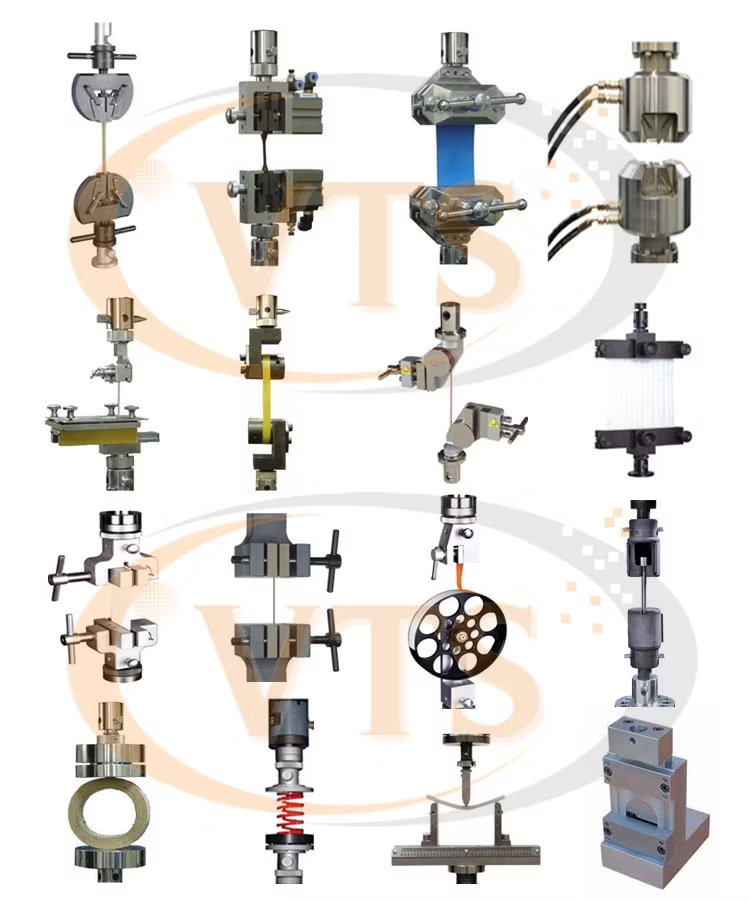

Products

|

Products  Wire Tensile Testing Machine

Wire Tensile Testing Machine

High Precision 20kN Electromechanical Tensile Testing Machine for Wire

High Precision 20kN Electromechanical Tensile Testing Machine for Wire

Available

Available

Product Description Electronic Universal Tensile Strength Testing Machine

| Model NO. | 50mm |

| Type | 0.5 |

| Load Way | Static Load |

| Display | Computer Control |

| Weight | AC380V |

| Oil Cylinder Position | Tensile Test Compression Test, Bending Test etc. |

| Packaging Details | 300kN 500kN 600kN 1000kN 1500kN 2000kN |

| Standard | Metal,Steel,Wire Rope,Rubber,Plasticcable |

| Certificate | Plywood Case |

| Specification | VTS |

| Origin | 9024109000 |

| Production Capacity | <1000KN |

| Max Load | Tensile Testing Machine |

| Testing Machine Mode | OEM,Software Reengineering |

| Protection Class | 0.5grade |

| Application | <900kg |

| Test Standard | 380V |

| Material | Computer, Digital, Dial |

| Impact Energy | Plastic Pipe Hydrostatic Pressure and Burst Tester |

| Testing Standard | 10MPa, 16MPa, 25MPa, 3 Stations |

| Testing Pipe | +50PA~ +1500PA |

| Usage |

1. Applications & Functions

The WDW Series Computerized Electromechanical Universal Testing Machines are meticulously engineered to perform tensile, compression, and bending tests on a wide array of both metal and non-metal materials. As quintessential tools for enterprises, these machines serve as the cornerstone for quality assurance. Whether in the quality control departments of corporations, university laboratories, or esteemed scientific research institutions, these machines are invaluable. They are calibrated to the rigorously high standards of ASTM E4 and ISO75001, ensuring compliance with test protocols such as ISO 6892, ASTM E4, ASTM E8, ASTM A370, ASTM D638, ASTM D790, and more. EN 10002-4, EN 10002-1, ISO 7500-1, ASTM D1002, among others. Crafted to test a diverse range of materials, including Steel, Metal, Rubber, Plastic, Cord, Composites, Cable, Wire, Aluminum, Copper, Textiles, Food, Packaging, and Nonwoven fabrics, they offer unparalleled versatility.

2. Main Features

This state-of-the-art machine is equipped with an alternating servo motor to drive the crosshead and features an imported photoelectric encoder for precise displacement measurement. The long-travel extensometer efficiently measures specimen elongation. Its control software seamlessly calculates essential metrics like tensile modulus of elasticity, elongation rate post-rupture, and non-proportional extend strength Rp0.2. The machine excels in executing three closed-loop controls and offers real-time visualization of multiple testing curves, including force-displacement, force-time, and stress-strain.

3. Main Technical Specifications:

| Model Specifications |

WDW-5 | WDW-10 | WDW-20 | WDW-50 | WDW-100 | WDW-200 | WDW-300 |

| Max Load Capacity (kN) | 5 | 10 | 20 | 50 | 100 | 200 | 300 |

| Load Accuracy | ±0.5% of applied force | ||||||

| Load Resolution | Max. testing force 1/500000 | ||||||

| Test Zones | Single | Dual (upper for tensile, lower for compression) or Single (lower for tensile, compression) |

|||||

| Test Speed Range | 0.005-500 mm/min | ||||||

| Strain Accuracy | ≤±0.5% | ||||||

| Crosshead Travel (mm) | 700 | 600 | 650 | 650 | 550 | ||

| Compression Space (mm) | - | 500 | 500 | 500 | 600 | ||

| Space Between Columns | - | 400 | 550 | 550 | 560 | ||

| Jaw dimension (mm) |

0-3 | 0~7 | 0~14 | 0~14 | 0~20 | ||

| - | φ4~φ9 | φ4~φ14 | φ4~φ20 | Φ9~φ26 | |||

| Power Supply | 1-ph, 220V±10%, 50Hz/60Hz | 3-ph, 380V±10%, 50Hz/60Hz | |||||

| Dimension (mm) | 530×380×1450 | 760×500×1800 | 880×710×1800 | 1040×630×2040 | 1120×710×2210 | ||

| Weight (kg) | 150 | 450 | 800 | 900 | 1300 | ||

Jinan Victory Instrument Co., Ltd (Victory Test - VTS) stands as a distinguished and reputable manufacturer and exporter of top-tier material testing machines and quality control testing equipment. Nestled in the vibrant city of Jinan, the capital of Shandong province, China, our strategic location places us just a short journey away from the bustling metropolises of Beijing and Shanghai, offering an ideal blend of accessibility and industrial prowess. At VTS, we are unwavering in our commitment to providing comprehensive and seamless solutions for customers Quality Control needs in the realm of metal materials. Armed with a highly skilled team of over 50 dedicated professionals and enriched by more than two decades of industry experience, we pride ourselves on delivering expert testing solutions with remarkable efficiency and precision.

As an ISO9001 and CE certified high-tech enterprise, VTS excels in the innovative design, research, manufacture, and marketing of mechanical property testing machines for metal materials. Our extensive range of testing machines encompasses a wide array of testing parameters, including tensile, compression, bending, torsion, impact, hardness, fatigue, and beyond. VTS products are meticulously crafted to conform to rigorous international standards such as ISO, ASTM, BS EN, TAPPI, GB, among others. Proud recipients of the CE certification, our cutting-edge products have gained international recognition and are now utilized in over 60 countries worldwide.

Leveraging our extensive experience of over 20 years, VTS is adept at offering tailor-made, ideal testing solutions that are swiftly aligned with your specific testing requirements, ensuring unparalleled excellence in performance and reliability.

Discover Our Unmatched Advantages:

Leveraging over two decades of industry expertise, we swiftly provide the perfect testing solution tailored to your specific requirements.

1. Esteemed professional manufacturer with a legacy spanning over 20 years

2. Competitive pricing paired with exceptional quality and optimal delivery timelines

3. Comprehensive One-Stop solution for all your material testing machine needs

4. Proudly certified supplier with ISO 9001, SGS, CE and more

5. Unwavering lifetime technical support and dedicated service

Dedicated Sale Period Service:

Upon receiving your Purchase Order, we ensure swift initiation of the production process.

Standard machines are readily available from our stock.

For bespoke machines, the production lead time is approximately 2-4 weeks.

We enforce strict quality control measures, and each machine undergoes meticulous inspection prior to delivery.

Comprehensive After-Sales Service:

Enjoy peace of mind with our standard one-year warranty period.

We provide an English-language operation manual along with a detailed instruction video.

Onsite installation and training services are available to ensure seamless integration if required.