Available

Available

Product Description WLP100-3000

| Model NO. | 50mm |

| Type | 0.5 |

| Load Way | Static Load |

| Display | Computer Control |

| Weight | AC380V |

| Oil Cylinder Position | Tensile Test Compression Test, Bending Test etc. |

| Packaging Details | 300kN 500kN 600kN 1000kN 1500kN 2000kN |

| Standard | Wire |

| Certificate | Wooden Box |

| Specification | VTS |

| Origin | 9024109000 |

| Production Capacity | <1000KN |

| Max Load | Wire Wrapping Testing Machine |

| Testing Machine Mode | OEM |

| Protection Class | 0.5grade |

| Application | <900kg |

| Test Standard | 380V |

| Material | Computer, Digital, Dial |

| Impact Energy | Plastic Pipe Hydrostatic Pressure and Burst Tester |

| Testing Standard | 10MPa, 16MPa, 25MPa, 3 Stations |

| Testing Pipe | +50PA~ +1500PA |

| Usage |

WLP100-3000

Floating Seal Ring Running Wear Leakage Performance Testing Machine

1. Application & Features:

2. Main Technical Specifications:

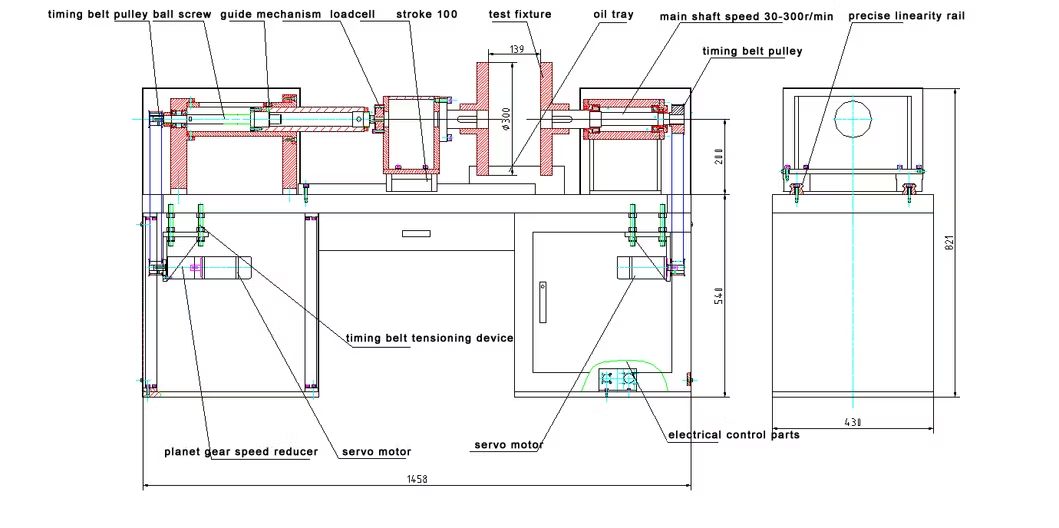

| No. | Items | Specs. |

| 1 | Max. torque | 100N.m |

| 2 | Outer diameter of floating seal | 50-220mm |

| 3 | Max.axial horizontal load | 3000N |

| 4 | Measuring range of axial horizontal load | 2%-100%FS |

| 5 | Indication error of axial horizontal load | ≤±1.0% |

| 6 | Resolution of axial horizontal load | 1/300000 |

| 7 | Resolution of axial horizontal deformation | 0.01mm |

| 8 | Axial horizontal loading rate | 20-100mm/min |

| 9 | Axial horizontal stroke | 0-100mm |

| 10 | Rotating speed of main shaft | 30-300r/min |

| 11 | Rotating direction of main shaft | Clockwise and anti-clockwise bidirectional rotation |

| 12 | Power supply | 380V±10% 50Hz |

| 13 | Power of machine | 4kW |

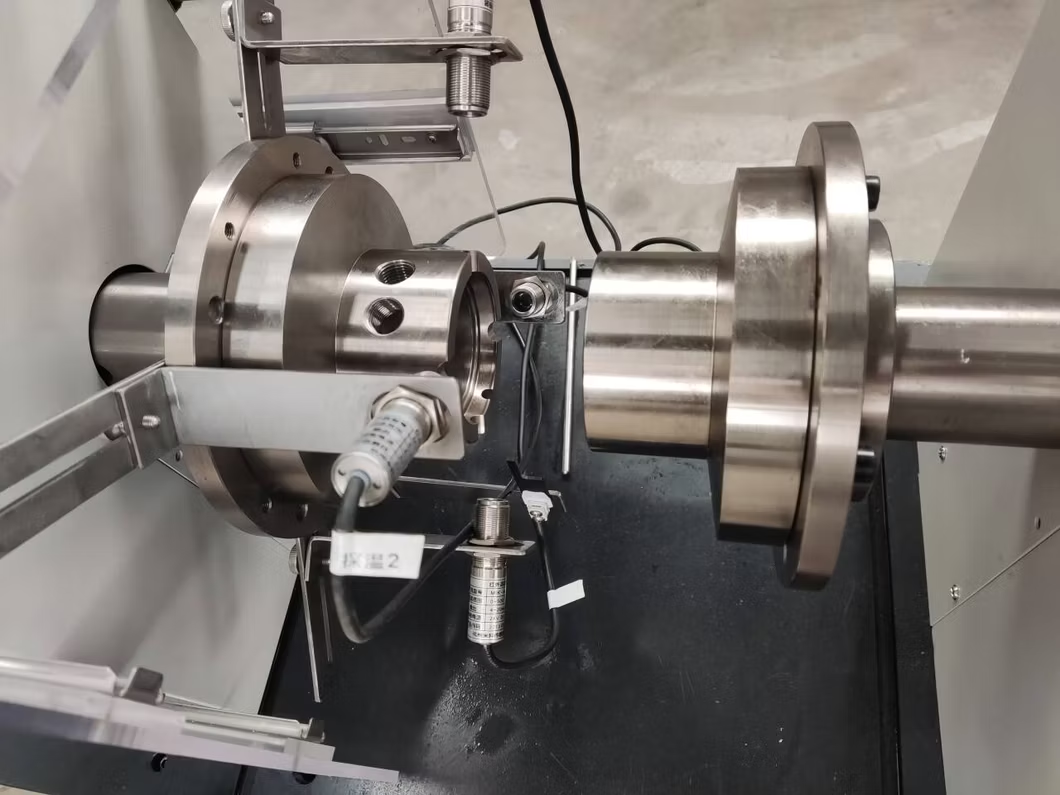

3. Structure Features & Working Principle

The main machine adopts the horizontal structure. The main rotation adopts the high-power servo motor to be decelerated by the high-precision planetary gear reducer. The dynamic torque sensor is connected with the rotating bracket and the floating seal seat through the coupling. Axial loading is conducted through the servo motor, reducer, synchronous belt to the ball screw, the guide mechanism will rotate the movement into axial loading, through the high-precision load cell to measure and control of the axial force.

3.1 Structure and working principle of mechanical parts:

Jinan Victory Instrument Co., Ltd (Victory Test - VTS) stands proudly as an expert manufacturer and leading exporter of comprehensive material testing machines and premium quality control testing equipment. Nestled in the vibrant city of Jinan, the capital of Shandong province in northeast China, we are strategically positioned just 2 hours from the bustling hubs of Beijing and Shanghai, making us easily accessible to our global clientele. Dedicated to delivering seamless quality control solutions for metal materials, we leverage our extensive expertise and experience to provide swift, tailored solutions. With a dynamic team of over 50 talented professionals and more than two decades of industry experience, our commitment ensures that we meet your unique testing needs efficiently.

As an ISO9001 and CE certified high-tech enterprise, VTS focuses on innovative design, in-depth research, precision manufacturing, and strategic marketing of mechanical property testing machines for metal materials. Our comprehensive range includes solutions for tensile, compression, bending, torsion, impact, hardness, fatigue tests, and more. Meeting varied global standards such as ISO, ASTM, BS EN, TAPPI, and GB, our cutting-edge products have earned the prestigious CE certification and are trusted in over 60 countries worldwide.

With our extensive 20-year legacy, we are perfectly poised to offer you the most effective testing solutions, precisely tailored to your specific requirements, ensuring rapid, reliable, and accurate results.

Our Advantages:

With over two decades of expertise, we swiftly deliver tailored testing solutions that meet your precise requirements, ensuring exceptional results.

1. Esteemed as a professional manufacturer for over 20 years, our legacy is built on reliability and excellence.

2. We present a harmonious blend of competitive pricing and superior quality, coupled with unparalleled delivery efficiency.

3. Experience the convenience of our comprehensive, one-stop solutions for all your material testing machine needs.

4. Recognized as a qualified supplier with ISO 9001, SGS, and CE certifications, we guarantee top-tier quality and compliance.

5. Benefit from our commitment to providing lifetime technical support and dedicated service, ensuring your satisfaction and success.

Sale Period Service:

Upon receipt of your purchase order, we expedite production arrangements to meet your needs with agility.

For standard machines, availability is immediate, ensuring prompt fulfillment of your order.

Customized machines require a production period of approximately 2-4 weeks, tailored to your specifications.

Our rigorous quality control ensures that every machine is meticulously inspected, guaranteeing flawless performance upon delivery.

After-Sales Service:

We offer a warranty period typically lasting one year, underscoring our commitment to quality and reliability.

Comprehensive English language operation manuals and instructional videos are provided to facilitate seamless use.

If necessary, we can provide onsite installation and training services, enhancing your operational efficiency.