|

Products

|

Products  Cupping Testing machine

Cupping Testing machine

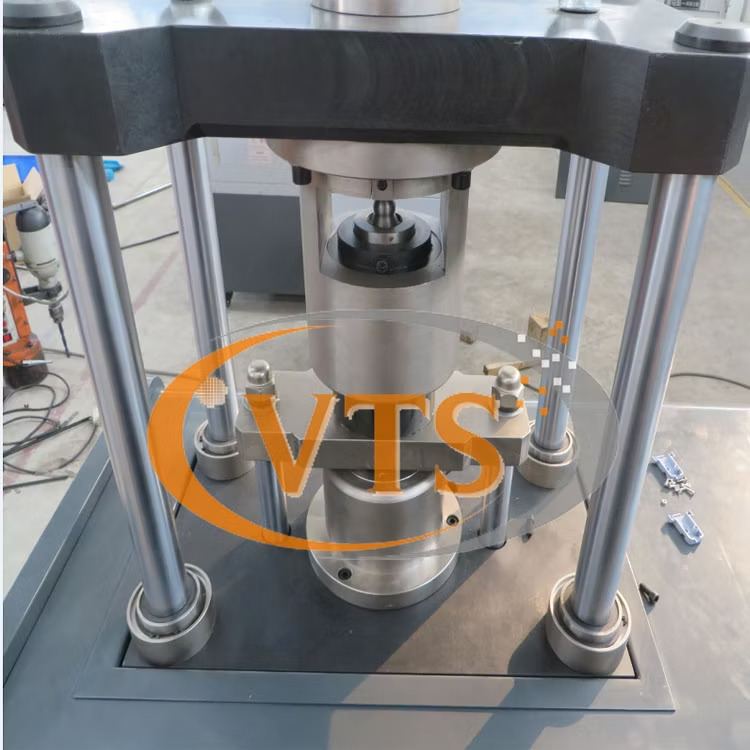

Heavy-Duty Cupping Testing Machine with 2000kN Capacity and Plywood Case

Heavy-Duty Cupping Testing Machine with 2000kN Capacity and Plywood Case

Available

Available

Product Description Erichsen Cupping Testing Machine

| Model NO. | 50mm |

| Type | 0.5 |

| Load Way | Static Load |

| Display | Computer Control |

| Weight | AC380V |

| Oil Cylinder Position | Tensile Test Compression Test, Bending Test etc. |

| Packaging Details | 300kN 500kN 600kN 1000kN 1500kN 2000kN |

| Standard | Rebar.Steel Bar, Metal, Bolt and Nut, etc |

| Certificate | Plywood Case |

| Specification | VTS |

| Origin | 9024109000 |

| Production Capacity | <1000KN |

| Max Load | Tensile Testing Machine |

| Testing Machine Mode | OEM,Software Reengineering |

| Protection Class | 0.5grade |

| Application | <900kg |

| Test Standard | 380V |

| Material | Computer, Digital, Dial |

| Impact Energy | Plastic Pipe Hydrostatic Pressure and Burst Tester |

| Testing Standard | 10MPa, 16MPa, 25MPa, 3 Stations |

| Testing Pipe | +50PA~ +1500PA |

| Usage |

Erichsen Cupping Testing Machine

2. Main technical parameters

| Model | GBW-60B | |

| Thickness of Sheet metal specimen | Standard Cupping Test 0.2-2mm | |

| Max Width of Sheet metal specimen | 100mm (≥90mm) | |

| Max. Punching force/Max Drawing force | 60kN | |

| Blank holder force | 10kN | |

| Max of Drawing punch stroke | 60mm | |

| Cupping Tools for Specimen Thickness: 0.2-2.0mm | Standard punch ball (Spherical punch Dia.) | 20mm |

| Standard pattern hole (Blankholder Dia.) | 33mm | |

| Standard fixed pattern hole(Inner Die Dia.) | 27mm | |

| Resolution of Erichsen cupping value | 0.01mm | |

| Testing speed | 1-60mm/min | |

| Display Contents | Clamping Force, Punching Force, Displacement, Cupping Value and Velocity | |

| Control Mode | Manual Velocity Adjustment, Automatic Judgment and Recording of Cupping Value | |

| Power supply | Three phase 380V, 50Hz or specified by users | |

Jinan Victory Instrument Co., Ltd (Victory Test - VTS), based in the heart of Chinas Shandong province, is a distinguished leader in the production and exportation of material testing machines and quality control equipment. Conveniently located just a short journey from Beijing and Shanghai, VTS is at the forefront of innovation and service. Committed to excellence, we offer a comprehensive solution for your Quality Control needs in metal materials. With a dedicated team of over 50 professionals and two decades of industry expertise, we swiftly provide tailored testing solutions to meet your specific requirements.

An ISO9001 and CE certified high-tech enterprise, VTS specializes in the development, research, manufacturing, and marketing of mechanical property testing machines for metal materials. Our diverse range of products covers essential testing categories such as tensile, compression, bending, torsion, impact, hardness, and fatigue. Meeting ISO, ASTM, BS EN, TAPPI, and GB standards, our CE-certified products are trusted by clients in over 60 countries worldwide.

Leveraging over 20 years of experience, we swiftly deliver the ideal testing solutions tailored to meet your specific testing requirements.